as precision metal manufacturing contains many different processes and production techniques, the ability to provide customers with a full one-stop processing services will definitely save time and management cost for customers, meanwhile will help the company to strengthen customer relationship and enhance product added value.

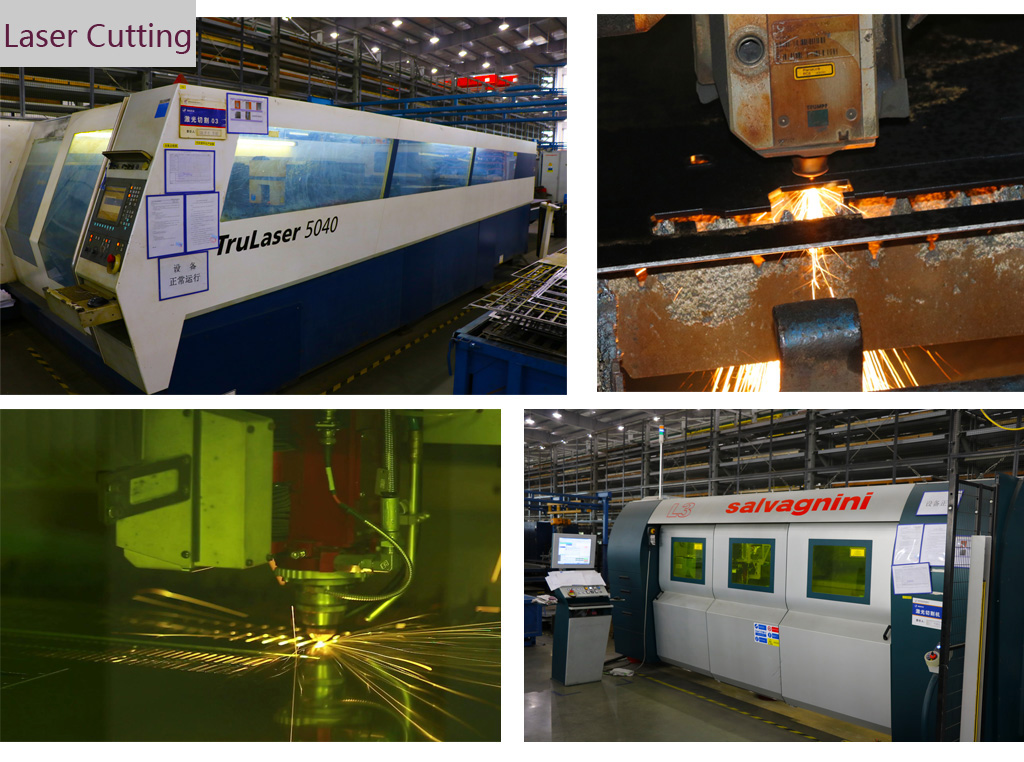

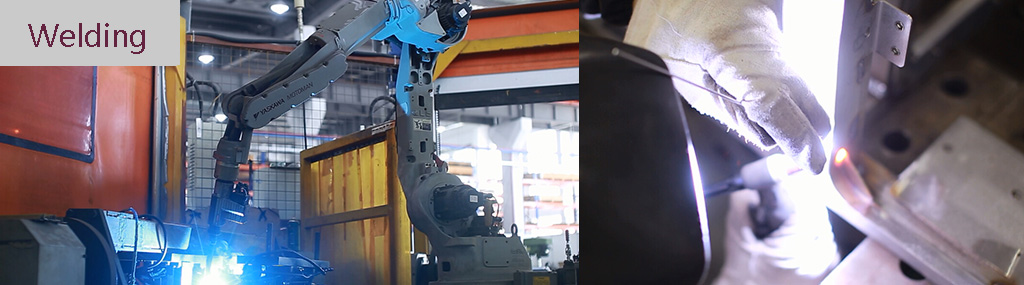

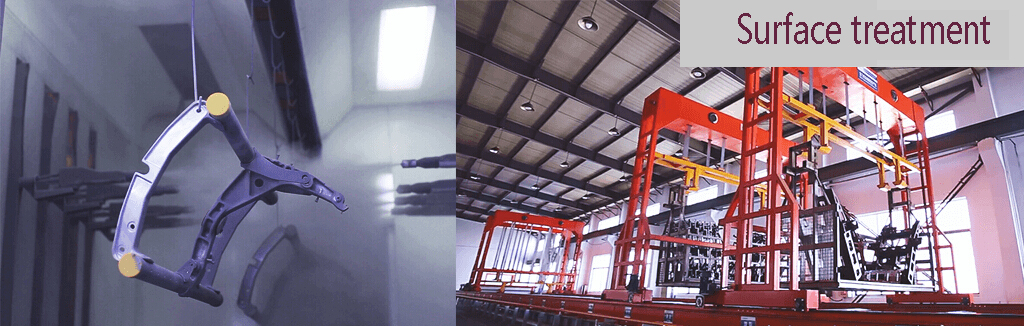

huaya company is equipped with excellent production equipments and various core technologies of metal manufacturing such as precision sheet metal processing technology, precision machining technology and precision welding technology, and spraying technology, able to provide a range of services including structure design, sample development, precision sheet metal processing, precision machining and precision welding , spraying and other types of surface treatment and assembly, after-sales maintenance, and so on, and to provide customers with "one-stop" professional solutions of precision metal manufacturing.since the establishment, after years of accumulation in product design and manufacturing technology research and development, huaya company has become a well-known domestic one-stop service provider of precision metal manufacturing.

huaya company is a high-tech enterprise and innovative enterprise in jiangsu province, equipped with three advanced r & d institutions: jiangsu enterprise technology center, jiangsu welding automation engineering research center, and national post-doctoral research station, as well as an excellent r & d team. the company's technical center has an experienced r & d design team, engaged in product structure design, manufacturing process development and improvement of production process design and optimization. we continue to develop new manufacturing solution, so as to ensure product development capabilities and quality, and to lay a solid foundation for the company's development. the company technology center sets up a technological optimization group, to constantly carry out production process optimization and technique innovation according to different product requirements and features. the company obtains three invention patents, 33 patents for utility models and many kinds of technological innovations, which lay a good foundation for product development and manufacturing.

with adoption of solidwoks and other three-dimensional computer development and design software instead of the traditional two-dimensional design, and application of synchronous hybrid modeling technology, the company set up a unified design data platform. interconnection between each module is realized, so it’s able to have the changes of three-dimensional model embodied in the two-dimensional model, finite element analysis and cnc machining programs. concurrent engineering design environment makes the design cycle greatly shortened, and effectively improves the design accuracy.

| sessions | advantages of intelligent sheet metal flexible production |

intelligent storage | application of sheet metal flexible processing system automated warehouse, real-time monitoring of main raw material inventory information and production planning, optimal arrangement of purchase plan |

| cnc processing program | production process with automatic setting and sheet metal production according to work orders |

| automatic blanking | application of sheet metal flexible processing system automated warehouse, on-demand automatic blanking, combined operation with laser cutting and sheet-metal shears |

| flexible bending | (1) compared with ordinary bending, flexible bending is available for simultaneous bilateral or quadrilateral bending. bending in the symmetrical position achieves high bending accuracy; (2)airfoil bending helps to avoid mould loss; (3)adoption of sheet metal software, all bending procedures are programmable, and multi-step bending is available; (4)flexible bending machine can be integrated into the roll leveling and stamping line procedure. |

sheet metal flexible punching | (1)a fixed punch can be equipped behind the mobile punch, fixed punch is able to carry a number of punching mould, which helps to improve production efficiency in the need of large punching or mass production; (2)another function of fixed punch is that bending mold can be equipped, used for the demand of small bending, serving several purposes. |

flexible shear and riveting | can be used with supporting software and systems |

| information integration | with intelligent terminal scanner to collect data, it achieves real-time maintenance and monitoring of production information |

the company's quality management is based on iso 9001: 2008, iso / ts16949: 2009, as9100 and en15085, iris standards, which stipulates the requirements of our quality management system. the as9100 is the international aviation and aerospace quality management system standards, which is one of the prerequisites for access into the aerospace supplier market. full name of iso / ts16949 is the quality management system - special requirements of implementation of the iso9001 by the organization of automotive industrial production parts and related service parts, and it is the technical specifications in international automotive industry, applicable for automobile factories and their direct spare parts manufacturers, it is the access authentication as the automotive industry supplier. iris, short for international railway industry standard, is a management system specialized for evaluation of railway industry and has been supported by four of the world's largest railway system manufacturers. en15085 is a quality management system for rail transit welding parts, including the whole process of quality certification of contract, design, process, production, inspection, and subcontracting.

huaya company obtains three invention patents, 33 patents for utility models and many kinds of technological innovations, which lay a good foundation for product development and manufacturing.